| |

|

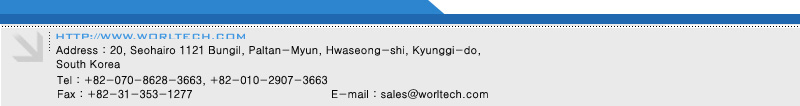

¡ß Features

|  By using Vision, offer diverse and complicated test systems By using Vision, offer diverse and complicated test systems

|

|  Check the real time and application to the in-lines system

Check the real time and application to the in-lines system

|

|

• A foreign substance, pattern existence and nonexistence, size test system

|

|

• Check exterior of Marketing or OCR, Print status

|

|

• Application to the non-woven fabric, paper and film production line

|

|

• Parking control system, a protection of invasion system

|

|

Diverse test systems, precision and low cost Diverse test systems, precision and low cost

|

¡ß Hardware Specification

|

Sensor : Line Scan Camera and Area Camera

Sensor : Line Scan Camera and Area Camera

|

|

Resolution(LS) : 1K, 2K, 4K, 8K, 12K

Resolution(LS) : 1K, 2K, 4K, 8K, 12K

|

|

Resolution(AS) : 640x480 ~ 1600x1200 ~

Resolution(AS) : 640x480 ~ 1600x1200 ~

|

|

Detection

Range : 20 § ~100 §®

Detection

Range : 20 § ~100 §®

|

|

Max. Positioning Velocity : 100§®/sec

Max. Positioning Velocity : 100§®/sec

|

¡ß Software Specification

|

Ease to use by using GUI.

Ease to use by using GUI.

|

|

Offer factory stability through statistical process techniques.

Offer factory stability through statistical process techniques.

|

|

Offer comparable with factory monitoring system.

Offer comparable with factory monitoring system.

|

|

Provide reliability through a close investigation.

Provide reliability through a close investigation.

|

|

Through Encoder chase or deletion a foreign substance.

Through Encoder chase or deletion a foreign substance.

|

|

Provide long time Data analysis through DB linkage.

Provide long time Data analysis through DB linkage.

|

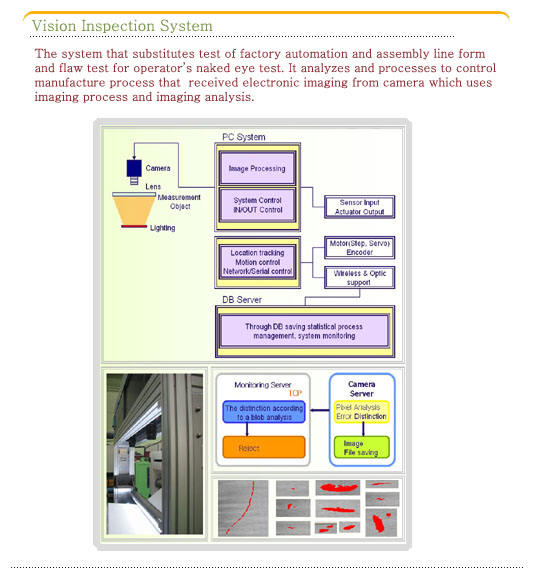

¡ß Vision System Consitution

|

1.

Carmera :

As an input medium which is input a picture, it

could classify into the normal Standard Camera and Nonstandard Camera.

According to the type of CCD Sensor, It can organize and use system by using

specific camera such as Area Scan, Line Scan and 3CCD.

|

|

2.

Lens

: As a part of Camera

Sensor that assembles light, It is usually determined on the object size and

distance. And according to the type of camera, it uses F-Mount

and C-Mount.

|

|

3.

Lighting

: As an important variableness to get clear image, It

has to make lighting condition to verity test part precisely. It includes a fluorescent lamp light, halogen light, LED light.

According to the penetration location, there are front light, back light, coaxial

light.

|

|

4.

Grabber

: The

equipment converts received signal from camera into computer signal. According

to the type of camera and Spec, model selections are different. There are also embedded

DSP Chip of high function and speed model.

|

|

5.

Control PC

: VBeing essential part of

Vision Base, it comprehensively controls S/W process, I/O Board control and an

overall System. According to the working condition and motion terms, it is able

to use for normal PC or industrial PC. Sometimes it affects speed in according

to System performance.

|

|

6.

Monitor

: It displays environment

setting and measurement situations.

|

|

7.

Printer :Being output functions of

test result, it displays Spec, flaw of products on weekly and monthly. (It can

not only use as Data Base but also keep inside PC)

|

|

8.

I/O Board

: The Board which connects with outside input/output

of Control PC. It serves as an interface of corresponding period signal, mechanical part control signal, light brightness control, trigger

light signal, classification of products, control signal of inferiority.

|

¡Ø Image

Click -> Big Size Image

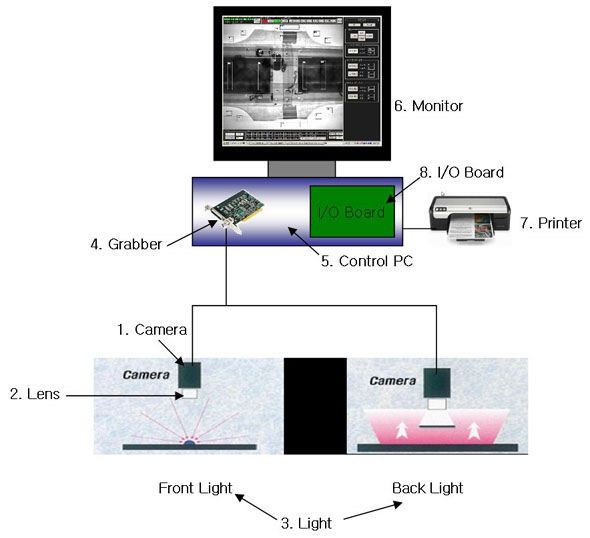

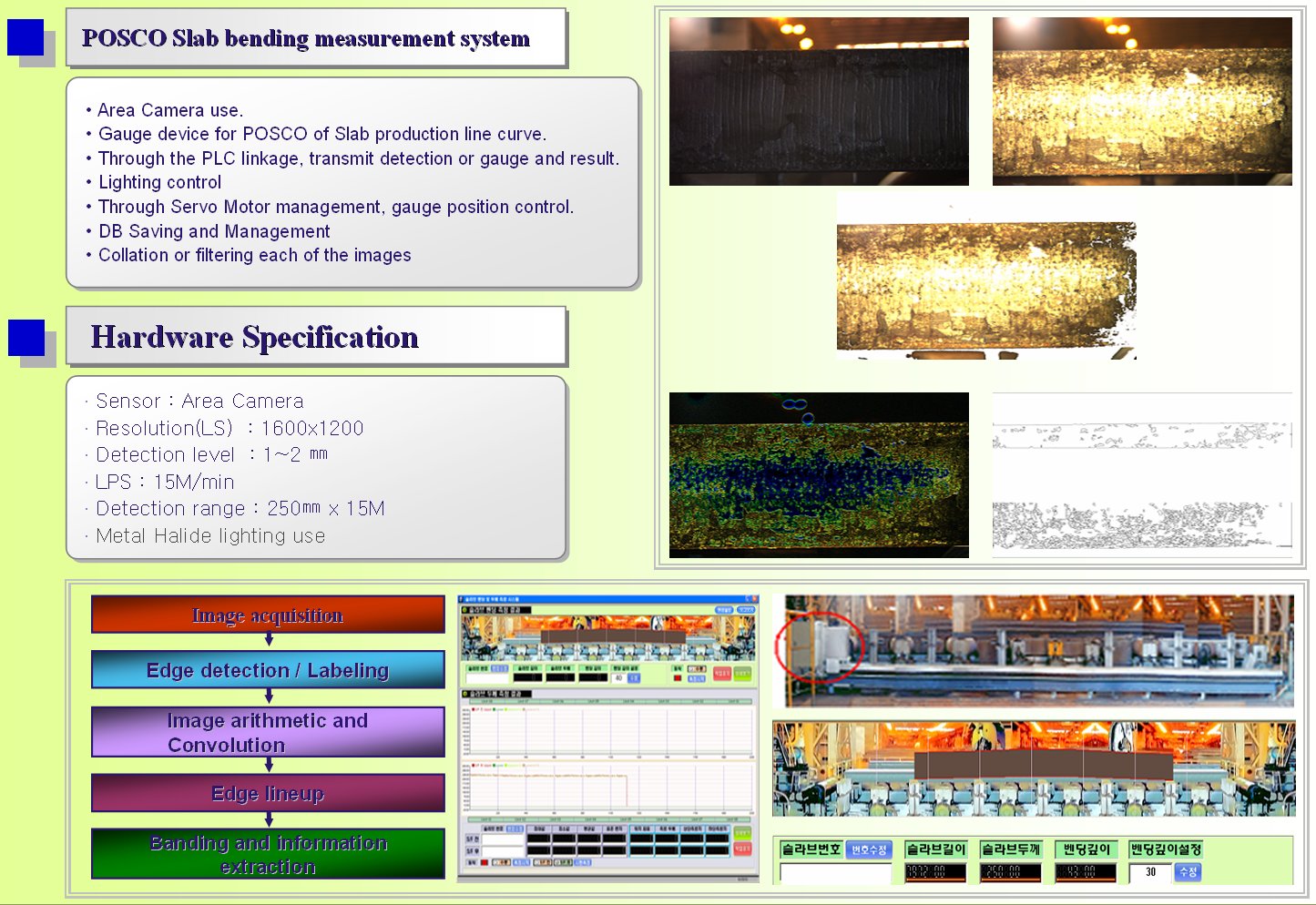

¡ß Delivery

of Goods : POSCO Bending

Measurement System

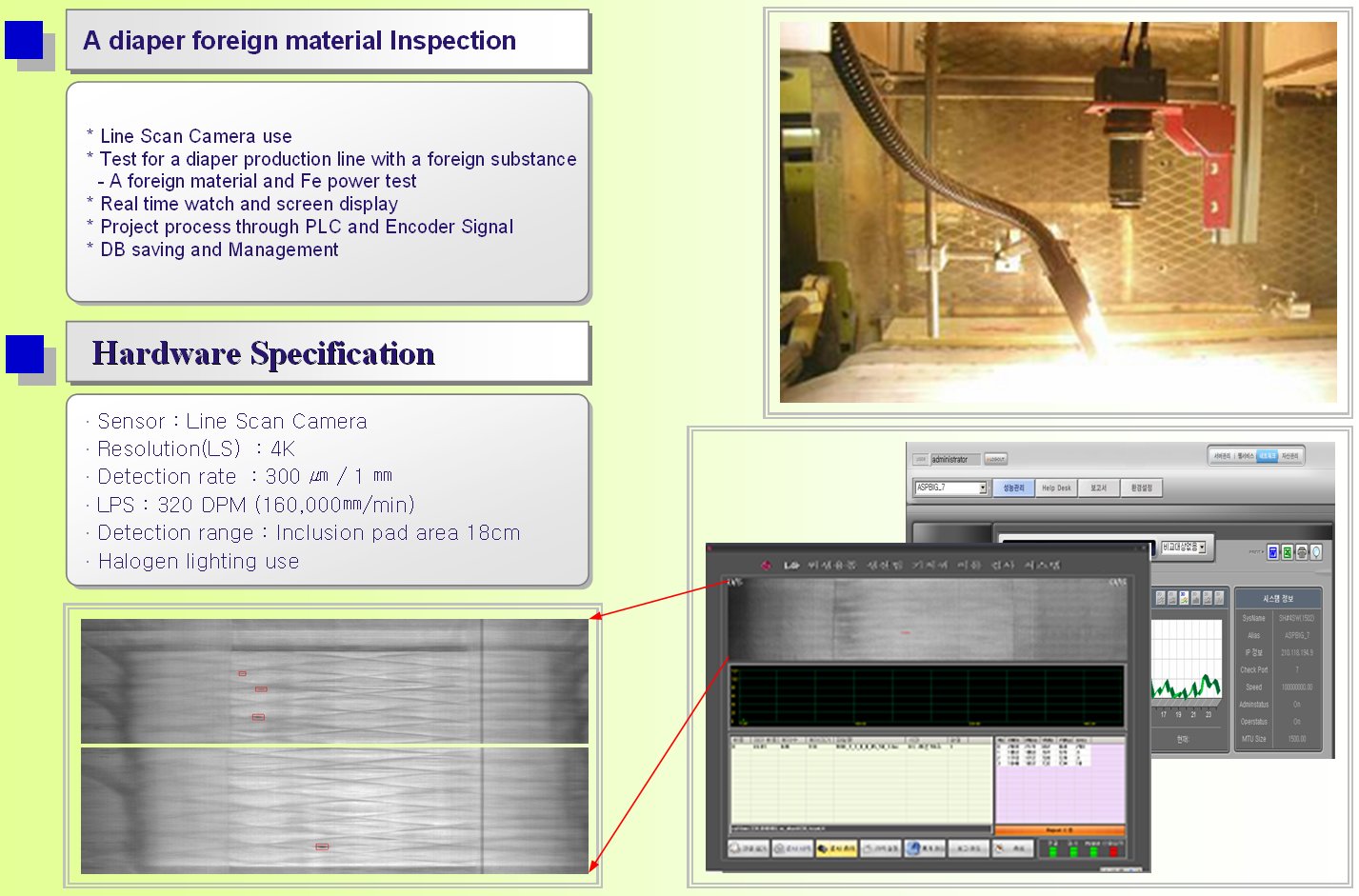

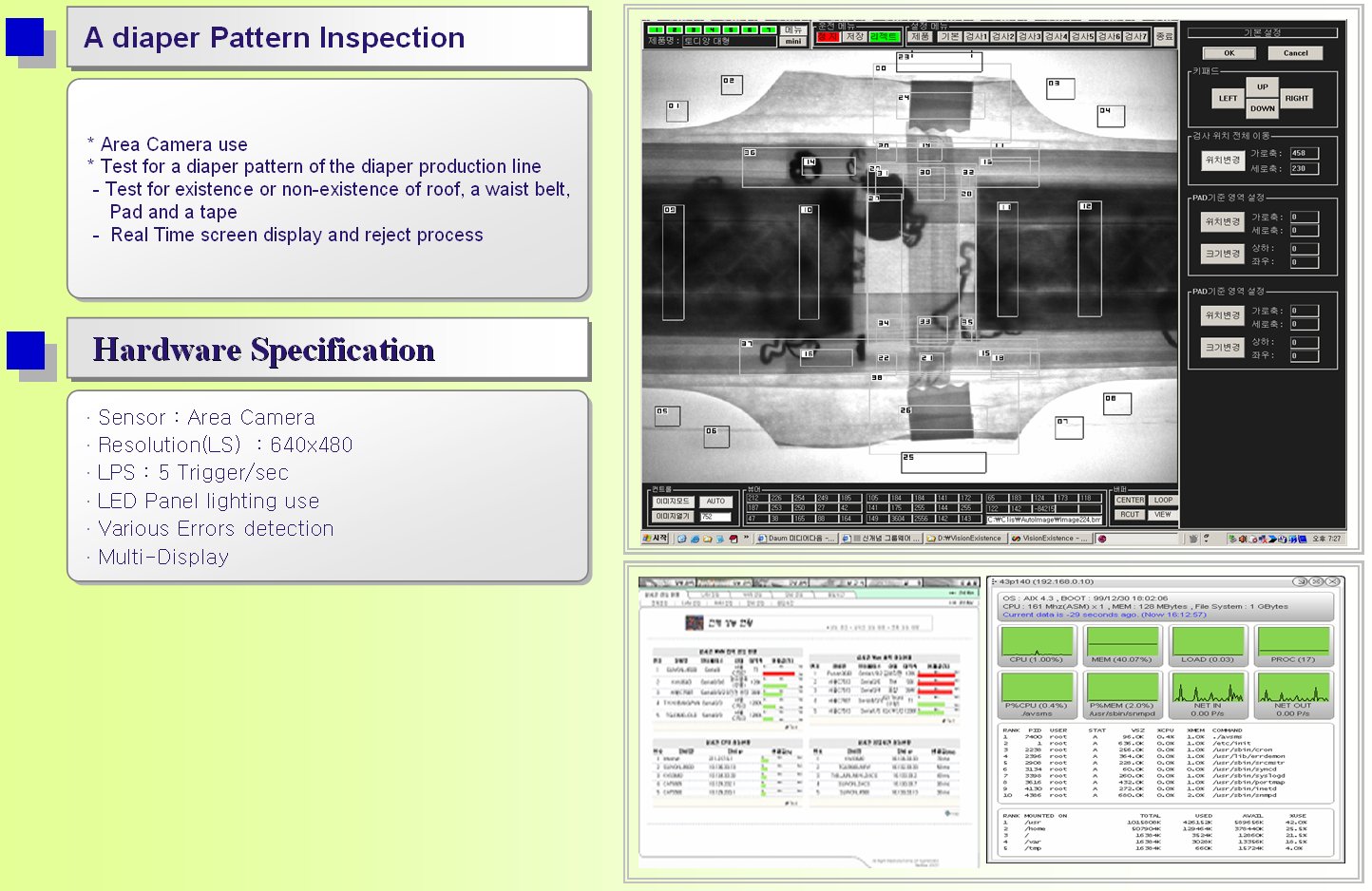

¡ß Delivery

of Goods : Diaper

foreign material/Pattern Inspection System

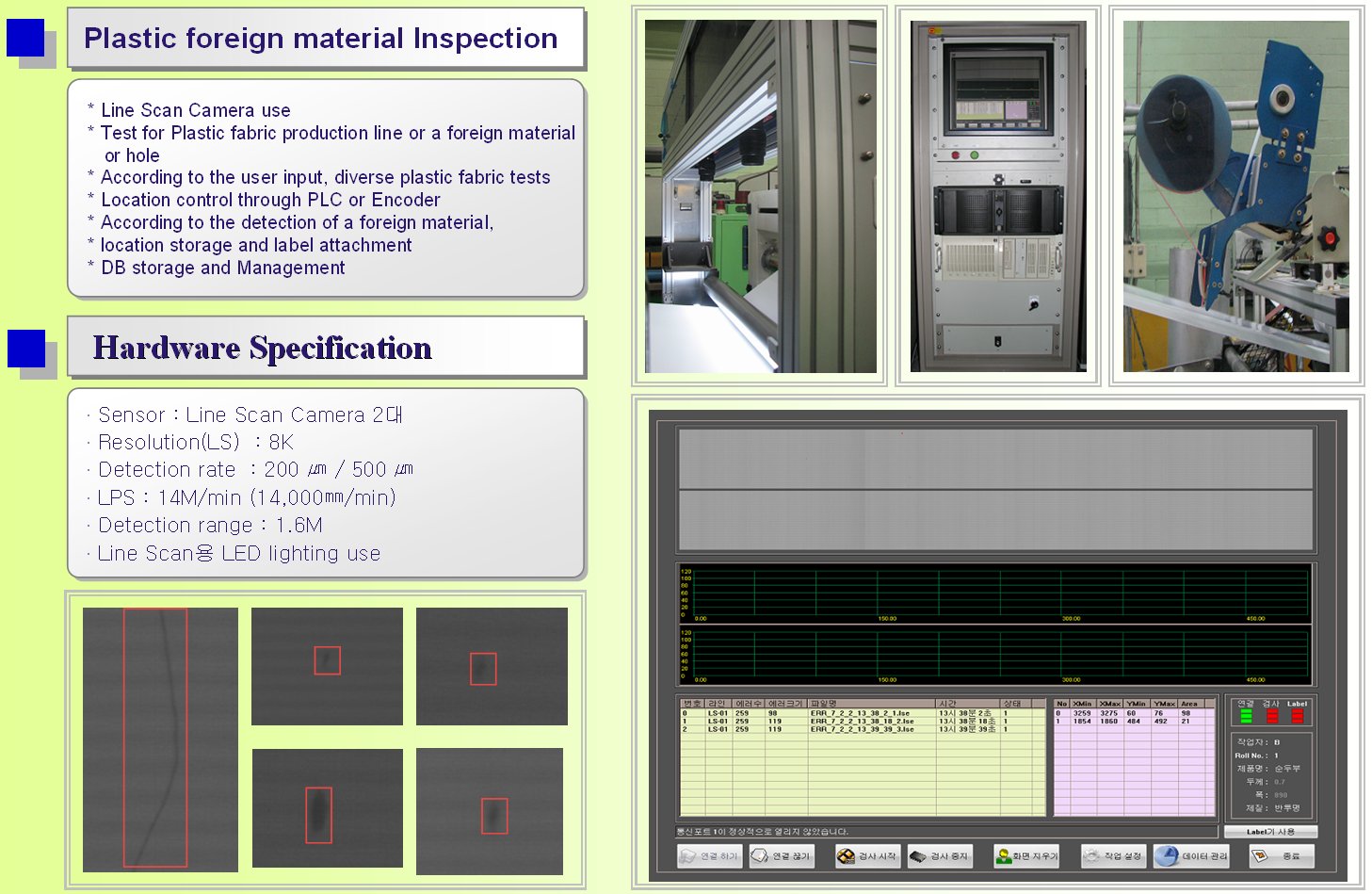

¡ß Delivery

of Goods : Plastic foreign

material Inspection System

¡Ø

Please call or e-mail on quotation and technical

inquires or Consultation.

|