|

¡ß Feature

|  By Labview Program, ease to use system. By Labview Program, ease to use system.

|

|  Using

made our own ultra sonic Purse/Receiver and DAQ, the device not only potable Using

made our own ultra sonic Purse/Receiver and DAQ, the device not only potable

|

| but

also reasonable to manufacture.

|

|  By using a scanner of detail structure the

realization of high resolution.

By using a scanner of detail structure the

realization of high resolution.

|

|  Tailed made ultrasonic system to the test object.

Tailed made ultrasonic system to the test object.

|

|  Various size products test by covering with a wide range of

frequency. Various size products test by covering with a wide range of

frequency.

|

|  Monitoring connect with RF at any where. Monitoring connect with RF at any where.

|

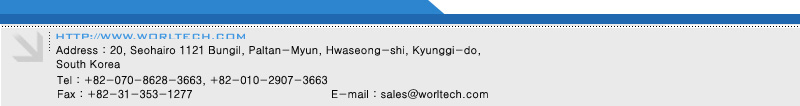

¡ß Constitution

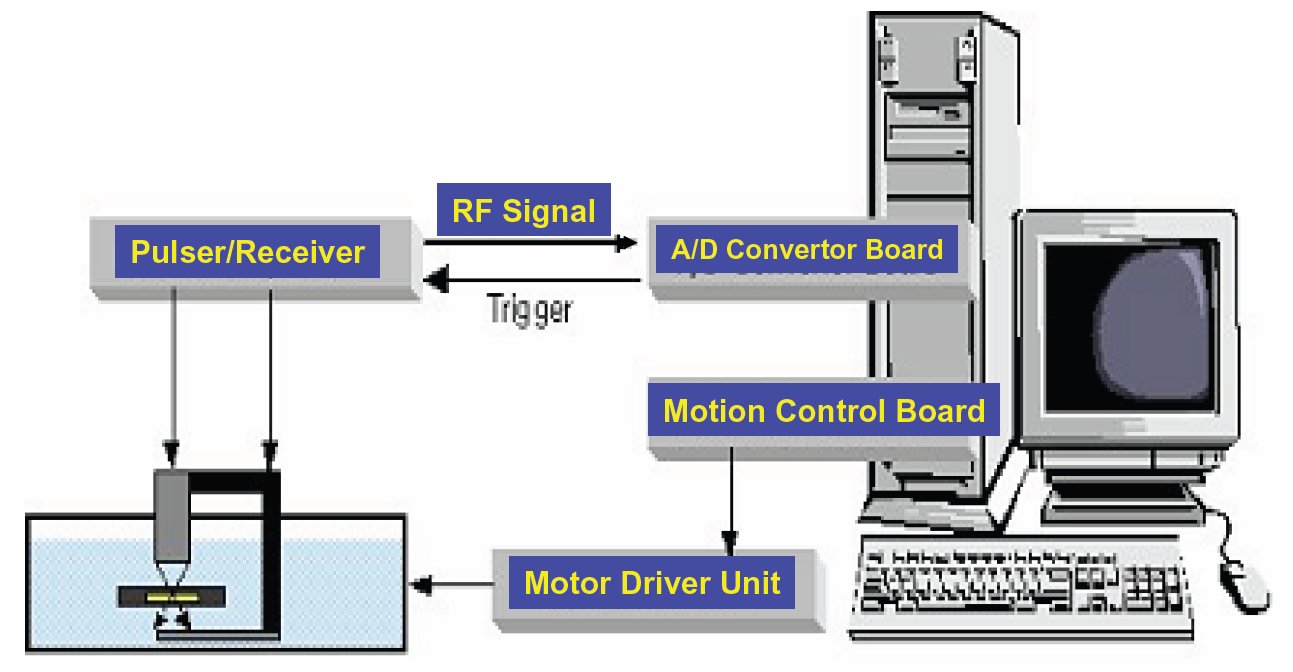

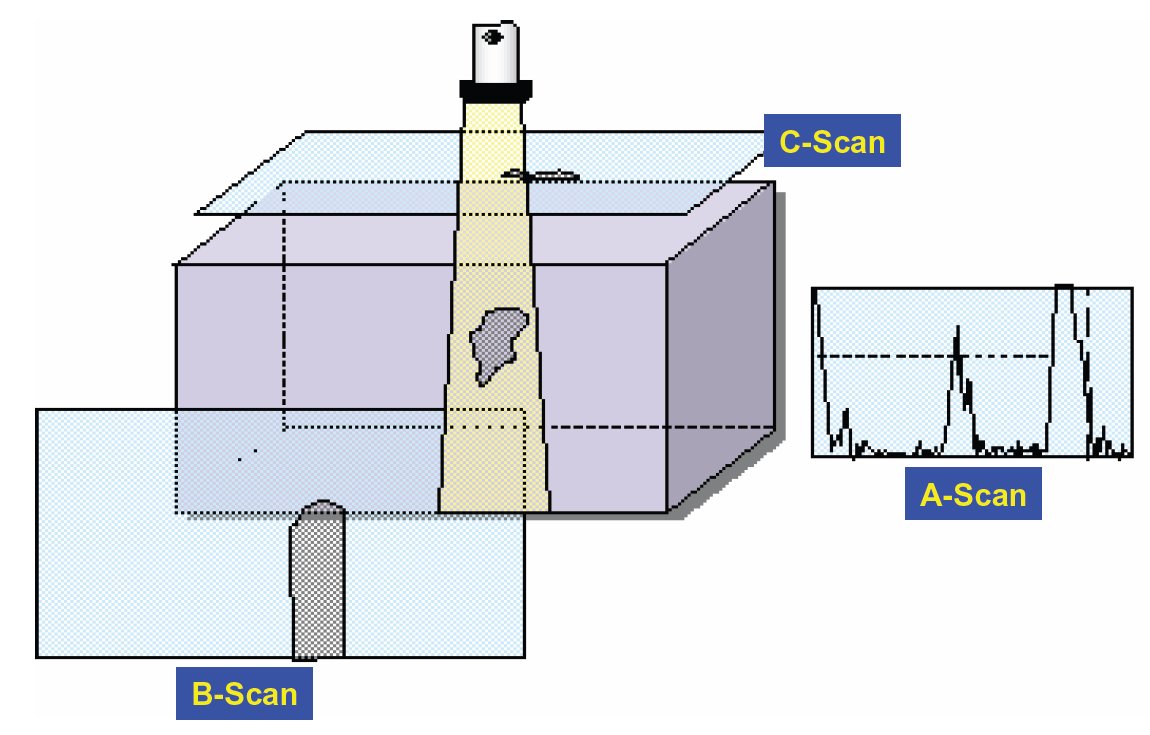

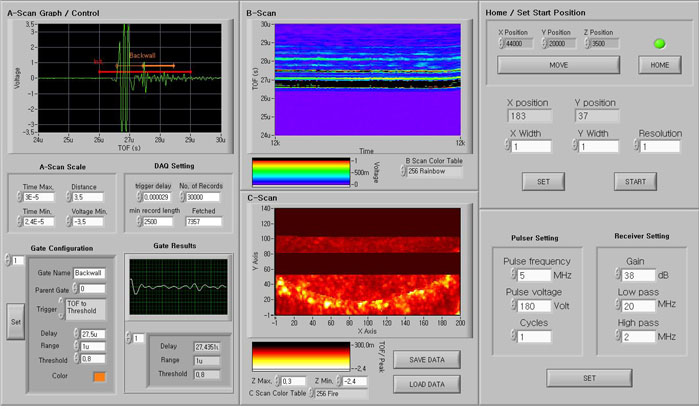

¡ß A/B/C-SCAN

Summary

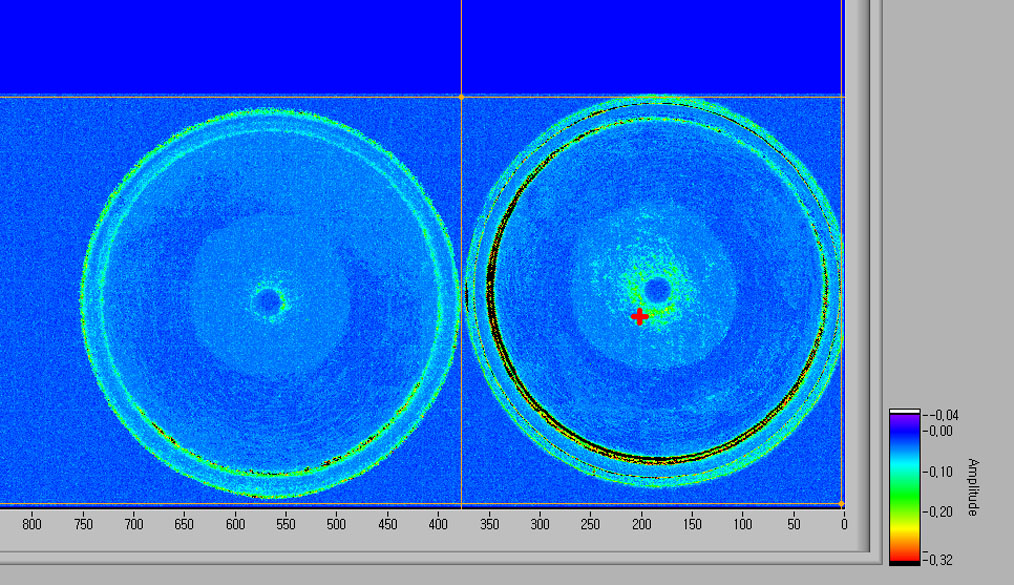

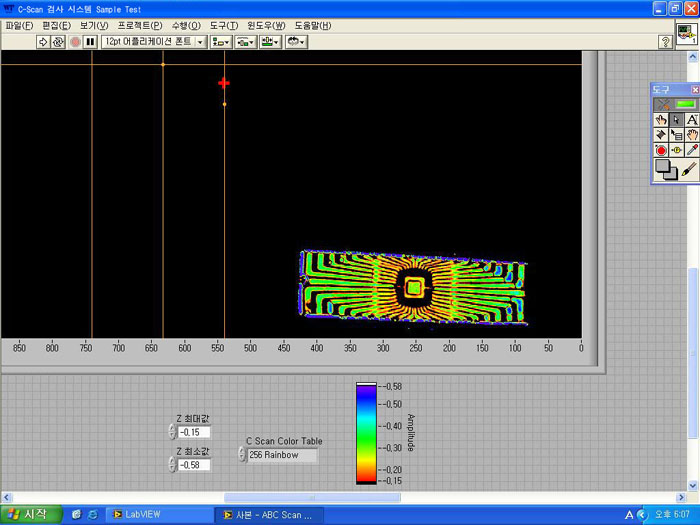

¡ß SAMPLE

¡ß C-SCAN

Control S/W

¡ß Specification: Automated Ultrasonic Flaw Imaging System

1. Scanning Range: 900mm*900mm*800mm (W * L * H)

2. Pulser/Receiver : PRC-035 (35Mhz Band Width)

3. Analog to Digital Converter : Gage Scope 1250 (12Bit Resolution, 50 Mega

Samples/sec)

4. Motion controller : 5 Axis

5. Motors: Step Motor (Sanyo Denki , 5 Phase)

6. Application : Ultrasonic flaw detection of composite material

C-Scan imaging of metal parts

7. Transducers: Immersion, Focus length: 60mm

Frequency: 1Mhz, 2.25Mhz, 5Mhz

Diameter: 0.5 inch

Type: Broaband, Power, General

8. Features: Automatic Swivel Control(The facility which the

hold does Probe angle at the measurement

sample to the vertical.)

Automatic Water Path Control (Probe-Test

Sample water between distance hold to the

automatic.)

Display option: RGB, Gray Scale, Threshold

R-Y, X-Y, Y-H scan Áö¿ø (Cone, Plate, Round, Pipe Apply

at all Inspection sample of a form.)

¡Ø

Please call or e-mail on quotation and technical

inquires or Consultation.

|